2-minute read

You’re probably sitting down right now – either at a desk or en route somewhere important. Have you gotten your daily 10,000 steps? In just a few short years, fitness trackers and other wearable technology have changed the way we lead our lives. People readily connect watches, phones, and even shoes to the Internet of Things (IoT), all in pursuit of the organization and productivity such connectivity promises.

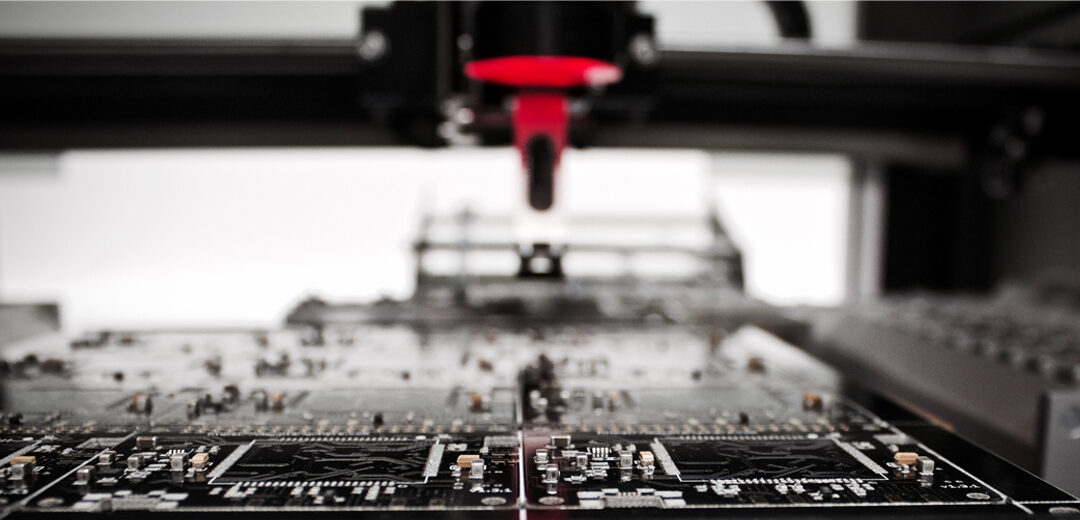

According to the Motley Fool, IoT device data is expected to increase by 50% every year until 2033. Along with IoT, machine learning, data analytics, and robots are driving change, otherwise known as digital transformation, in every sector – but especially in manufacturing. One recent IDC study found that 75% of large manufacturers will utilize IoT and analytics-based technologies to drive their companies by the end of 2019.

So, what is digital transformation? More importantly, what does it mean for business?

Though there are a variety of similar definitions, digital transformation at its core is the act of using digital tools to solve old problems. It’s the process of reexamining legacy systems and using cutting-edge technology to improve the status quo. Instead of being restricted to linear thinking, business owners, project planners, and employees of all stripes can use digital transformation to think outside the box, changing their systems for the better.

In manufacturing, this may look like:

– analyzing geolocation data to improve logistics and reduce waste

– implementing predictive analytics via IoT to avoid equipment failure

– using production automation to save money, reduce injuries, and increase throughput

The world is entering a new industrial revolution—and digital transformation is the key to getting and staying ahead. Preparing for this monumental shift is the biggest hurdle currently facing the manufacturing industry. So what can be done?

Invest in new technologies

With digital technologies like business intelligence dashboards, team apps, and project management tools, information is accessible instantaneously, whether it’s human- or machine-generated. Just the increased productivity alone is worth the cost of implementing these new solutions, but the employee and customer satisfaction aren’t too bad either.

Hire talented STEM workers

Transforming tools is one thing, but transforming your workforce is another. Creating a competent, well-rounded team familiar with the latest STEM technologies is vital with how fast data is accumulating and being put into practice.

Listen to technology and people

Transforming tools is one thing, but transforming your workforce is another. Creating a competent, well-rounded team familiar with the latest STEM technologies is vital with how fast data is accumulating and being put into practice. This can be done by hiring new talent, but another equally important component is ensuring that long-standing employees are brought along in the digital transformation journey, no matter their experience with STEM tools. This process is helped enormously by proper change management.

Applying modern technology, we can improve all aspects of a business, including process management, customer management, marketing, and customer experience. Using digital transformation, you can harness widespread cultural change into a powerful business plan.

MONITOR AND VISUALIZE ORGANIZATIONAL KEY PERFORMANCE INDICATORS IN A DYNAMIC AND INTERACTIVE WAY WITH CHANGE MANAGEMENT

Read about the Change Management Process.

Digital transformation done right

We create powerful custom tools, optimize packaged software, and provide trusted guidance to enable your teams and deliver business value that lasts.