12-minute read

Quick summary: The integration of renewable energy sources in microgrids offers a promising method for producing green hydrogen, enhancing energy resilience and reducing carbon emissions.

The production of hydrogen through microgrids integrating wind and solar power, complemented by battery storage, represents a promising advancement in the pursuit of sustainable energy solutions. By leveraging cutting-edge technology and efficient energy management systems, microgrids can optimize the capture and storage of renewable energy, ensuring a continuous and reliable supply for hydrogen electrolyzers. This article explores the technical aspects of this method of green hydrogen production, highlighting its potential to enhance energy resilience and provide hydrogen producers with a reliable and robust system.

A brief review of hydrogen production

Electrolytic hydrogen production involves using electricity to split water molecules into hydrogen and oxygen through a process called electrolysis. This is typically carried out in an electrolyzer, which consists of an anode, a cathode, and a membrane. When an electric current is applied, water (H₂O) molecules are dissociated into hydrogen gas (H₂) at the cathode and oxygen gas (O₂) at the anode.

Electrolytic hydrogen production is particularly attractive when powered by renewable energy sources (referred to as “green” hydrogen), because it emits very little carbon and decreases fuel costs for energy needs. Current hydrogen production is dominated by a process known as steam methane reforming, which is associated with large amounts of CO2 emissions.

Production of green hydrogen lends itself perfectly to building renewable energy generation sources directly at the plant, avoiding transmission costs and ensuring easy and transparent energy consumption accounting. Colocation schemes are attractive to hydrogen asset managers who can reduce costs of green energy generation and in turn decrease costs downstream to potential offtake buyers. Building a smaller power plant that co-locates the generation and production of hydrogen creates what’s known as a microgrid (MG).

Article continues below.

INSIGHT

Discover how the 45V clean hydrogen production credit could impact your energy strategy—and what you need to know to stay ahead.

What is a microgrid?

Microgrids are smaller energy systems that mimic the larger electrical grid in many ways but are also able to function independently of the entire network if needed. How the MG connects to a regional network will vary with the project, but most green hydrogen MGs use the larger grid to provide crucial voltage and frequency support.

Connecting to a regional network takes away some risk associated with grid events that can disrupt or damage components. In most regional grids, should there be a disconnection or transient event, the grid relies on a series of backup systems and protocols to make sure it can return to stability safely and quickly for its customers, a system that the hydrogen MG can tap into for additional safety.

A brief overview of grid stability

To understand the intricacies in designing hydrogen microgrids, it’s important to understand the overall concepts of grid stability in electrical systems.

The larger electrical grid has been designed and dominated by spinning generators that provide a frequency setpoint based upon their rotational speed. Additionally, each generator in the grid is electromagnetically connected. This means that coupled generators will be forced to match each other’s frequency and provide an additional level of stability to the system by holding a single frequency across the system.

The spinning mass of these generators also provides the grid with inertia that helps prevent an uncontrollable frequency drop if there’s a system outage. The heavy magnets within the generators continue to spin the moment after a plant in the system goes offline, and this ability to slow the drop of frequency helps operators get control of the system and apply contingency reserves to swing the grid back to stability.

Penetration of inverter-based resources

As more wind and solar plants come online, the penetration of resources that lack large spinning inertia increases. Since wind turbines and solar panels don’t produce energy from generators and use electrical inverters to move between DC and AC energy, they behave completely differently from fossil fuel–burning power plants. Thus, they are mostly referred to as “inverter-based” energy generating resources.

This presents a challenge for grid operators, because a system designed around spinning generators for decades operates under a different set of rules from solar plants that use power electronics to control frequency. A higher penetration of renewable energy into the grid means the lines between how you control frequency and voltage in the electrical system become more blurred.

“Grid-forming” versus “grid-following” are terms that are important to grid operators that manage the stability of electrical systems. These refer to the power electronic components that manage the connections of generation sources with the electrical grid and how they react to changes in the system.

Grid-following power electronics are the most common in the grid today, as they act in more-or-less simple logic to follow the frequency of the grid they are connected to, which is dominated and stabilized by spinning generators. If the grid frequency changes to 59.99 Hz, the grid-following inverters simply alter their output to follow that change in the system.

Grid-forming power electronics are much more complicated. They are now the masters of their own systems and use controllers to set whatever frequency and voltage they want in the system. This is more dynamic and powerful, because now every aspect of the electrical system can be managed by a controller and system logic, but it creates many problems. Instead of solving one or two problems, you now need to design around hundreds of contingencies and make sure the system is reliable and resilient in all cases.

Another set of key terms to lay out for microgrids are “grid-connected” and “islanded.” When a microgrid is connected to a larger system and taps into its resources and inertial stability, it is “grid-connected”. When that intertie is severed for whatever reason, the MG becomes “islanded” and must act on its own with no outside help.

In most cases, grid-connected MGs use grid-following logic and islanded MGs use grid-forming inverters, as they have no other way to manage the stability of frequency within their system. However, just as the MG can rely on the connection to the larger system to provide steady-state reliability, it must weather grid events like outages or abnormalities by itself. During an event, the microgrid will disconnect from its tie to the main electrical system and become islanded. This term refers literally to the state of a microgrid that must rely on its own systems to function and is isolated from outside electrical connections.

Hydrogen production—the paradigm shift

MGs specifically designed for hydrogen production result in a paradigm shift in control theory. Whereas almost every electrical grid today functions as load-following, these new hydrogen grids are generation-following. What does this mean?

Today’s grid functions as a system that responds to how its users are buying electricity, meaning the generating sources must react to follow the profile of the load. When you turn on your washing machine at home, the uptick in load required by the grid due to your machine is met with a spinning generator at the same instant you press the power button. The ever-changing loads are met by the grid instantaneously and the generation is turned up or down to follow the profile of the load.

Maximizing electrolytic hydrogen production requires exactly the opposite. The goal of a production plant is to run the electrolyzers at full power as much as possible, but sometimes this is not possible. Green hydrogen MGs run by solar, wind, and batteries will produce intermittent energy dictated by weather forecasts and will limit how much power is available for the electrolytic cells. Thus, the electrolyzers must follow what energy is available and respond accordingly. This is referred to as “generation-following,” where the load follows the generation profile instead of the other way around.

Figure 1: Diagram of how a generation-following hydrogen electrolyzer would follow power

In traditional systems, there is only one variable aspect of this dance, the load itself. The load will change constantly, and the controller will match this change. Now, both sides can be controlled – the electrolyzers can be ramped up or down, and the generation can be curtailed or turned up as possible. Hydrogen MG controllers ensure that production needs are met, but components are not compromised by large ramps up or down in power draw. This controller manages the delta between generation and load to maintain the stability of the MG.

How do hydrogen MG controllers stabilize the system?

Load frequency control (LFC) is essential in MGs to maintain stability in islanded mode when it cannot rely on larger system’s stability devices. Maintaining a stable system is especially difficult in green hydrogen MGs because they use renewable energy sources that are relatively low in overall generation capacity. This means that you have distributed energy sources that are liable to large fluctuations in power, something that is undesirable in smaller systems because they do not have the same safety systems as larger grids.

In hydrogen MG systems, battery storage is required to provide necessary supplementary functions like smoothing the generation curve and islanded stability control. Energy storage systems provide the critical component in islanded control strategies to maintain frequency levels and provide grid-forming capability to the system. Power quality control by batteries in the MG is important for hydrogen electrolyzers to avoid maintenance downtime and keep plants running longer. Battery systems are used to navigate unpredictable power issues in the MG by acting as a buffer between the expensive electrolyzer and the renewable resources, ensuring that reliable and smooth power is reaching the hydrogen production side of the project.

Protection systems for islanded MGs are one of the biggest hurdles to development. Due to the small size of distributed generation within MGs, current trips within grid forming inverters are a complex challenge. With inverter-based resources, low-magnitude fault currents are very difficult to capture among protective relays and lead to less-resilient MGs by limiting the ability of the grid to respond to and track fault currents. With no “parent” grid to rely on for stability during faults, the MG must navigate faults with precision to keep the fragile system afloat, and protection systems need to be top of line. As electrolyzer technology is extremely important for profitability of hydrogen production systems, the need for fault protection in MGs that have majority electrolyzer load requirements is crucial.

Implementing inertia schemes in a low-inertia environment

While in islanded-mode, MGs face low-inertia conditions that can make stabilizing the system during faults problematic. Navigating stability in frequency and voltage immediately following system faults is difficult without the safety net of inertial responses that traditional spinning generators give grids. But there are multiple ways which hydrogen MGs can navigate these issues.

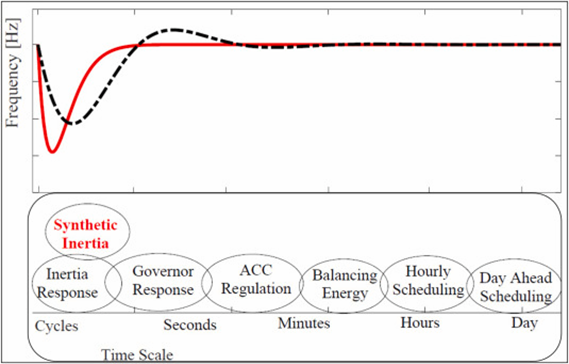

The first is to control inverter outputs to replicate the inertia the full renewable MGs have, a term broadly and often vaguely defined as “synthetic inertia.” The idea behind this is to control the reaction of inverters during contingencies so that they mimic the response of a traditional grid. They allow different generating sources to synchronize to the frequency changes slowly, mitigating any problems that arise with rapidly changing power outputs in the intermittent resources. During an event, a traditional synchronous generator would absorb excess power in the coiled windings of the generator to consume energy and slow the drop in frequency due to mismatch of generation and load. Virtual inertia schemes accomplish this by absorbing energy into an energy storage system (ESS) and manipulating a constant of virtual damping to control the characteristic of the response with an ESS.

To properly regulate a hydrogen MG with virtual inertia, it follows that the battery energy storage system (BESS) provides crucial support in the seconds following an outage, so the design, sizing, and control logic of the BESS is extremely important for stability of the system. In hydrogen production projects with large amounts of installed generation capacity, frequency must be stabilized by grid-forming inverters in the BESS. Battery sizing can become an issue if there is insufficient energy available in the cells to properly apply virtual inertia control loops. Furthermore, it is unclear whether synthetic inertia in large hydrogen MGs can properly respond to fringe outage cases like consecutive disturbances or large fluctuations of renewable power by photovoltaic (PV) or wind generating sources.

However, navigating the difficulties of implementing pure inverter-based response algorithms into islanded hydrogen MGs can also make the system better than traditional grids. While inertia is helpful in slowing the rapid drop in frequency during an outage, that same constant of inertia applies negatively to restoring the grid to its nominal frequency.

Figure 2: Frequency control in power system with synthetic inertia versus traditional generator inertia (Source)

Islanded hydrogen MGs are tools that can make production methods for green hydrogen highly reliable, but also present many challenges. Without proper strategies for operating the MG with controller logic that can balance the new design philosophies of hydrogen production grids, they will become prone to failure and result in higher hydrogen costs.

Balancing reactive power in hydrogen MGs

Reactive power in a power system is essential for maintaining voltage levels necessary for active power to do useful work, as it helps regulate voltage to ensure the stable operation of electrical equipment. It also supports the transfer of active power through the network by maintaining the electric and magnetic fields in AC systems, minimizing losses and improving efficiency. Continuing the theme of this article, reactive power becomes even more important for MGs due to the relatively low amount of energy capacity and therefore magnification of possible power quality issues.

During islanded scenarios, bus voltages must be properly supervised to prevent large fluctuations that can damage components or trip safety devices. Since there is no outside help from a wide area interconnection, reactive power must be managed from within the hydrogen MG, most commonly from the BESS. Reactive power is stored in the reactive elements within the MG, but the BESS is required to supply the energy needed for this reactive power. From the previous section, it is known that the BESS needs to be sized properly to provide LFC and ride-through capability during outages. Now even more responsibility is required of the storage system, and if the hydrogen production needs of a plant are large enough, a huge BESS is needed. With green hydrogen costs already high, the need for an oversized BESS could doom a prospective hydrogen production project with extreme cost.

With large hydrogen production plants, the energy levels of the MG may necessitate large amounts of reactive power compensation, especially during islanded modes. If there is insufficient reactive power in the system, the power quality issues may be catastrophic for electrolyzer or other system components.

Synchronous condensers or static synchronous compensators (STATCOMs) are tools used by power system designers to provide reactive power without the need for overgeneration by other assets. They use spinning resources or power electronics to supplement reactive power in a system and can compensate for power quality issues in a smaller system like a hydrogen MG. Implementing a STATCOM at various buses in a hydrogen MG can provide a boost of reactive power if the system has a shortage. When STATCOMs or synchronous condensers are used instead of compensating with a larger battery capacity, overall plant costs can be reduced, which is paramount for increasing penetration of green hydrogen into the market.

Hydrogen MGs can become powerful tools for the energy transition

The integration of microgrids for hydrogen production using renewable energy sources such as wind and solar presents a transformative approach to sustainable energy systems. Unlike traditional grids that are load-following, these hydrogen-focused microgrids are generation-following, adjusting their operations based on the availability of renewable energy. This shift in control theory necessitates advanced management systems and battery storage solutions to ensure reliability and stability, particularly when microgrids are “islanded” from larger grids.

Hydrogen microgrids, with their need for resilience and efficient energy management, highlight the importance of grid stability and the role of grid-forming and grid-following power electronics. However, challenges such as maintaining grid stability, managing load frequency control, and ensuring effective fault protection must be addressed to optimize performance and ensure the reliability of these renewable energy systems.

Powering a sustainable tomorrow

We partner with utilities to help them build a more resilient grid and move towards a cleaner, brighter future through

- Smart automation

- Asset image analytics

- DERMS implementation

- Analytics & predictive insights

- Cloud optimization